Replacing the 3.0L Water Pump

Joe Angell

As long as I had everything apart, I figured I should replace the water pump as well. This was especially important due to the oil/coolant mix that had gotten everywhere in the engine while I was replacing the lower crankcase, which took forever to clean out of the block.

I ordered a new water pump from RockAuto for ~$50. It included gaskets as well as the bottom bolt, which is good because the bolt can't actually be removed without removing the pulley as well.

DMCNews.com has a guide for replacing the 2.8L water pump. It mostly applies here as well, although since I already had mine out of the car I was able to skip a bunch of steps.

2.8L vs 3.0L

Being one of the earlier 3.0L cars, the water pump is pretty much identical to 2.8L water pump. There are some notable differences, not so much in the pump itself but how it attaches to other parts of the car:

- The back of the pump housing has the larger hose that runs to the cylinder heads swapped with the smaller hose that runs to the heater core. They are also different sizes, with the 3.0L engine providing freer flow to the engine.

- Where the thermotime switch is mounted to the left of the water pump on the 2.8L, the 3.0L has a second pipe running to the heater core. The 3.0L sensor is mounted on the opposite side.

- The 3.0L has a serpentine belt pulley, while the 2.8L has a V belt pulley.

The main take-away is that while you can probably use a 2.8L pump, it's easier to get a 3.0L pump. You can't swap the rear housing with the 2.8L one, as the 2.8L one only has four bolts and the 3.0L one has five.

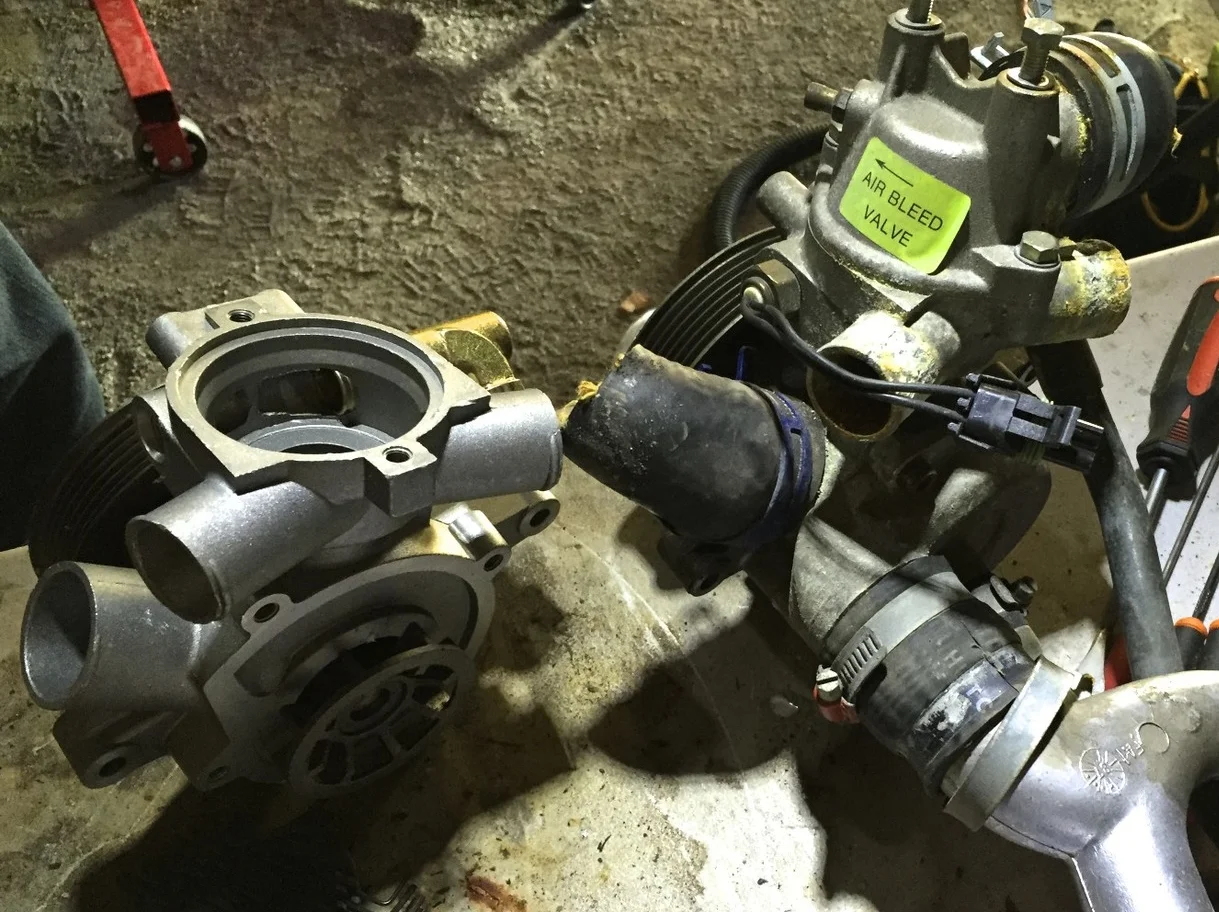

The back of the 2.8L (left) and 3.0L (right) pumps, with the Y pipe and coolant pipes still attached to the 3.0L one.

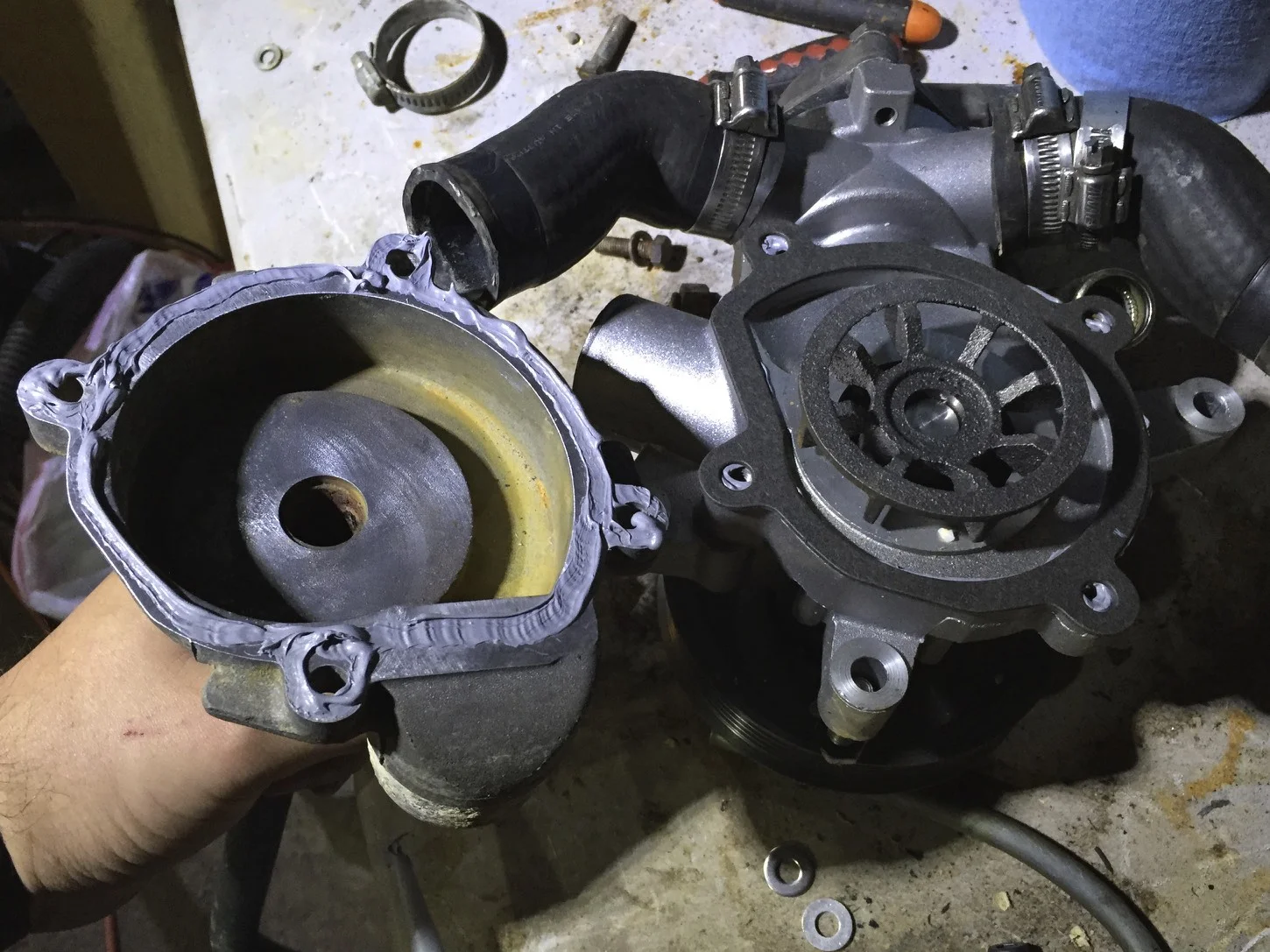

The front of the pumps, with the 2.8L on the right.

The New Pump

The new pump is just the pump -- it does not include any pipes or hoses, although it did come with the bottom bolt and the gasket to mate it to the rear housing. This means that the housing has to be reused from the 3.0L engine. The thermostat housing also has to be reused. It does have a tube coming off the right that connects to one of the heater pipes.

The old 3.0L pump (left) and the new one (right); the 2.8L pump is visible in the background.

The new pump (left) and the old one (right). Clearly the thermostat housing and rear housing need to be reused from the old pump..

Removing the Parts from the Old Pump

Many of the parts from the old water pump need to be transferred to the new one. A few parts can be taken from the 2.8L pump as well.

Rear Housing

I started with the rear housing. This is held on with four (4) socket cap screws, and are removed with a 5.5mm socket wrench. At least that's the idea -- I was able to break one of them free with a a short cheater on the end of my wrench. I simply stripped the next two I tried. Of course I didn't apply any penetrating oil before I started, which might have avoided this mess.

The next weekend I used penetrating oil, and gave a set of Irwin Bolt Grips a shot. These look like sockets, but have a series of flutes inside that spiral slightly. The flutes crop onto the head of a rounded bolt or a socket cap screw. I found the closest fitting bolt-grip, tapped it onto socket cap screw with a hammer, and used a socket wrench to turn the cap. This successfully broke free both of the stripped screws.

To finish removing the cover, I used a 13mm socket to separate the two heater pipes from each other. I was able to then pry the rear housing from the pump.

Irwin Bolt-Grips and their spiraling fluted edges that grip the head of a screw or bolt.

Using an Irwin Bolt-Grip on the end of a socket to remove a striped socket cap screw.

The messy internals of the old water pump.

Thermostat Housing

The thermostat sits on top of the pump, and is held in place with two bolts that are removed with an 11mm socket. Mine was in pretty rough shape, and the thermostat was quite stuck in the housing. Luckily, the 2.8L water pump's thermostat housing is identical, save for the number of holes on the top for accessories (the 3.0L has two holes for a spark plug wire mount, while the 2.8L has only one hole). I was willing to sacrifice the hole for a much cleaner housing.

Removing the bolts for the thermostat housing with an 11mm socket.

The dirty innards of my old water pump with the thermostat housing removed.

The extremely dirty 3.0L thermostat and housing (left) and the clean 2.8L thermostat (right).

The top of the two thermostats. They are identical save for the longer pipe and extra screw on the 3.0L.

Heater Pipes

I didn't bother removing the heater pipe from the rear of the housing, as there was no need to -- the whole housing was being transferred to the new water pump. Also, it is kind of a strange pipe, and I didn't want to risk damaging the joint while pulling it apart.

The heater pipe mounted to the side of the pump was more interesting. I didn't notice an analog to the pip e on the DeLorean, and in fact a sensor is mounted there in the 2.8L pump instead. The pipe itself fits into a sleeve lock on the end of an elbow. You should be able to tap it out, but I had to clamp the pump in a vice and whack the sleeve with a hammer a few times before it came loose. I was then able to twist it out until it was free of the pump.

Where the heater pipe meets the elbow on the water pump.

The pipe nearly removed from the elbow.

The pipe fully removed.

Coolant Temperature Senor

The temperature sensor is mounted on the right side of the water pump, and is removed with a 19mm wrench. I wasn't able to find a replacement with the same wiring connection, so I decided to reuse the original one. Its location is such that it's easy enough to replace later if need be.

Removing the coolant temperature sensor with a 19mm socket.

Other Hoses

There are the usual assortment of hoses hooked up to the pump. Some use screw-tightened hose clamps, while others use spring-loaded clamps that I hadn't encountered before. I like the spring loaded ones in principle, and they were easy to take off with a set of adjustable pliers, as long as the mouth was opened wide enough (too narrow and they wouldn't squeeze the clamp enough to release the pressure on the hose). The hoses on my 2.8L water pump were rather new, so I replaced the ones from the 3.0L with them.

The thermostat housing (left< the old hose (middle) and the spring hose clamp (right).

Using adjustable pliers to open a spring hose clamp.

Cleaning out the Heater Pipes and Back Cover

The back cover was filled with more of the oil/coolant gunk that had clogged up the rest of the coolant jacket. I brought it and the heater pipes home to flush them out with hot water in the kitchen sink. I ran them through the dishwasher first, to try to remove any loose bits, but that didn't really work too well. I was able to scrape off a lot of the residue with a scrubbing pad.

The pipes were a bigger problem. Water poured into the end of the pipes didn't come out the other end. I used some long-handled bristle brushes to get some of the oil gunk out, but they couldn't reach in deep enough to get all of the blockage, and I couldn't get enough water pressure from the kitchen sink to blow them out forcibly. I was also unable to find replacement pipes online, which would have been the simplest solution.

The back cover after running it through the dishwasher. Still some gunk on there.

The back cover after cleaning it with some hot water and a scrubbing pad in the sink. Better, but could still use some more cleaning

Assembling the New Pump

I needed a couple more parts before re-assembling everything. Since I had ruined two of the socket cant screws that hold the back and front of the pump together, I had to get some replacements. Being 30mm long M7 x 1.00 screws, they're very hard to find. My only option was McMaster-Carr, which were more than five dollars per screw (they were also grade 12.9, which is much stronger than necessary, but they had nothing else); a DeLorean vendor told me that they couldn't get a better price than that, either.

I also picked up a new 190 degree Fahrenheit thermostat (the stock opening temperature described in the service manual) from Rock Auto, as well as a water pump gasket (I'm not sure if I never had one or if it came with the pump and I'd accidentally thrown it out). I also got a new thermostat seal.

Mating the Back and Front

I used Right Stuff on the gasket between the back on front of the pump. This may not be necessary, but I did it anyway. There's a thread on DMCTalk about other to use Right Stuff or not on the back, the thermostat housing and the sensor, and wether you need a gasket at all when mating the 3.0L pump's front and back.

The four hex cap screws with new washers are tightened with a 5.5mm allen wrench. I seem to have misplaced mine, but a 5mm one seemed to work just as well, although it was slightly loose. I didn't have a hex bit for my torque wrench, so I just made it as tight as I thought it needed to be without stripping it out.

The gasket stuck to the back of the water pump with Right Stuff, and another coat of Right Stuff on the backing, ready to be mounted.

Thermostat and Housing

The thermostat seal sits under the thermostat in the top of the water pump. The thermostat itself has a small hole in it, which according to the 3.0L engine manual is an air bleed. It also says that this should be at oriented so that it sits at the the highest point of the water pump, which is at the back.

The housing mounts over the top of the thermostat. I reused my 2.8L one, since it was in much better condition than my old 3.0L one, and they're pretty much identical. You just ned to make sure that the pipe coming off the top points towards the left before tightening it down with an 11mm socket to 9 ft lbs.

The air bleed hole on in the thermostat should sit at the highest point in the pump, towards the back of the pump.

The wedge-like shape of top of the pump under the thermostat makes it clear that the high point is near the back.

The thermostat housing's bolts being torqued to 9 ft lbs. with an 11mm socket.

Coolant Temperature Sensor

The coolant temperature sensor on the right side of the water pump doesn't need any sealant, just a 19mm wrench to tighten it down. Again, I had no way to use a torque wrench here so I simply made it as snug as I thought it needed to be without leaking..

Heater Pipes

The return heater pipe slides into the elbow on the right side of the pump. The ends were a little dirty, so I wrapped a ScotchBrite pad around them and scrubbed it until most of the corrosion was removed.

The manual says there are O-rings in the elbow, and all you have to do is slide the pip into the blow as far as it will go, causing it to lock into place. I gave it a few taps with a rubber mallet just to be sure it was all the way in.

The bracket that holds the two heater pipes together goes back on pretty easily with a 13mm socket.

The return heater pipe locked into the shiny bronze-colored elbow.

A 15mm socket is used to tighten the bracket that holds the heater pipes together.

Mounting the Water Pump

The water pump sits on top of the front of the engine, and is held in place with three bolts. One of the bolts is somewhat permanently installed on the pump, since you have to remove the pulley to remove the bolt. All of the bolts screw into the face of the engine just above the timing cover.

The hard part is the hoses that feed the cylinder heads. I reused the ones from my old 3.0L; I originally tried the 2.8L hoses, but they're a bit too long and difficult to get in place on the heads. I attached the hoses to the pump first, and fiddled with them while trying to seat the pump itself, eventually getting everything in place. Just don't forget to put the hose clamps on before installing. Also, check for extra sealant from the timing cover that might block the water pump mounting holes; I wound up having to take the pump off and clean some away so that I could fit the bolts in properly.

The three bolts take a 13mm socket, and are tightened to 20 ft lbs. You can't fit a socket on the bolt behind the pulley, so I just made it as tight as I could with an box wrench. I found that the best way to avoid cross-threading was to make sure to push the pump against the block and then thread the bolts in most of the way, but not tighten them until they were all in place. This afforded enough play to slide the pump around a millimeter or two so that the bolts would line up properly.

With the pump mounted, I could tighten the hose clamps to the cylinder heads. I accidentally used an old hose clamp and would up stripping it while tightening it. I managed to back it off while pushing the slack out with pliers, completely removing the band from the screw and bending it out form around the hose. I really didn't want to take the pump off to install the new clamp, so I backed out the screw on the new one, bent it around the hose, slipped the band back under the screw and tightened it back up again. You have to be careful not to overly deform the clamp if you do this, however.

Using a box wrench to tighten the water pump bolt behind the pulley.

The water pump installed on the engine, with the hoses positioned and the heater pipes pointing out the back.

The old 2.8L hoses are (back) are longer than the 3.0L hoses (installed), making them more difficult to install.

Installing the "Y" Pipe

The "Y" mounts to the back of the water pump, and is how coolant gets from the pump to the coolant jacket around the cylinders. The old O-rings on the block were flattened, and the area they rested in was pretty dirty.

I pulled the rings out with a pick and found a replacement in an O-ring assortment I bought of Amazon some time ago. Before putting it in, I used picks to break up all the dirt around the seal sits, a bristle disc to clean up the mating surface, and a shop vac to pick up all the debris I'd loosened with the other two.

The "Y" pip also has gaskets. This is probably overkill, but I installed them away with Right Stuff between the "Y" pipe and the gasket. I didn't put any on the block due to the O-rings, although it probably would have been fine there as well.

A rubber hose mates the "Y" pipe to the back of the water pump. I replaced the old one with the silicone one I'd gotten from PJ Grady some time ago for my 2.8L engine, and used a new stainless hose clamp to hold it in place.

The tricky part wound up being getting the pipe positioned correctly. The wide parts of the "Y" are slightly wider than where the corners of the heads stick out, so it takes some finagling to get it in there. I just tried some different angles until it worked. Then you have to manage to fit the hose on the other end of the pipe onto the back of the water pump, which itself takes some doing. Finally, you need to align the holes in the block to the holes in the "Y" pipe and insert the bolts, tightening them to 9 ft lbs with an 11mm socket. I had some trouble with the alignment, as the gaskets shifted while trying to get the pipe in position. They were easy enough to realign by pushing them around a bit with a pick.

Looking towards the front of the engine, the two smaller holes at the bottom of the picture are where the "Y" pipe mounts to the block. The old O-rings are still sitting in their recesses.

The mating surfaces cleaned and the old O-rings removed.

The old (left) and new (right) O-rings from my O-ring assortment.

Applying Right Stuff between the "Y" pipe and the gasket.

Installing one of the four bolts that hold the "Y" pipe in place with an 11mm socket on a bit driver.

The "Y" pope and water pump fully installed on the

Idler Pulleys

My last task for the day was installing the idler pulleys. These mount on the timing cover and are torqued down to 20 ft lbs with a 15mm socket.

Torquing the lower idler pulley after installing the upper one.

And with that, the water pump and idler pulleys are installed and I'm ready to move on to the next thing.